Project Northstar

Objectives

Project Name: Northstar – Variable impulse hybrid rocket engine

Developed by: Saint Louis University Rocket Propulsion Lab (SLU RPL)

Purpose: Sounding rocket propulsion system designed for research and IREC competition

Motor Classification: O-4200 hybrid engine

Fuel and Oxidizer:

Fuel: PMMA (acrylic)

Oxidizer: Liquid nitrous oxide

Structural Design:

Combustion chamber: 6061 aluminum

Nozzle: Graphite

Thermal liner: Phenolic

Oxidizer tank: 6061 aluminum, rated for 900 psi operating pressure

Physical Integration:

Fits standard 4-inch motor mount tubes

Compatible with legacy SLU airframes

Performance:

Average thrust: 1000 lbf

Total impulse: 5000 lbf·s

Control System:

Electronically adjustable oxidizer flow

Microcontroller-based real-time thrust modulation

Enables altitude control during flight

Safety Features:

Automated motor shutdown for overpressure, over-temperature, and off-nominal trajectory

Redundant safety systems

Reusability:

Designed for reuse comparable to commercial off-the-shelf motors

Significance:

Advances SLU’s propulsion research capabilities

Demonstrates the viability of hybrid propulsion in collegiate rocketry

Design

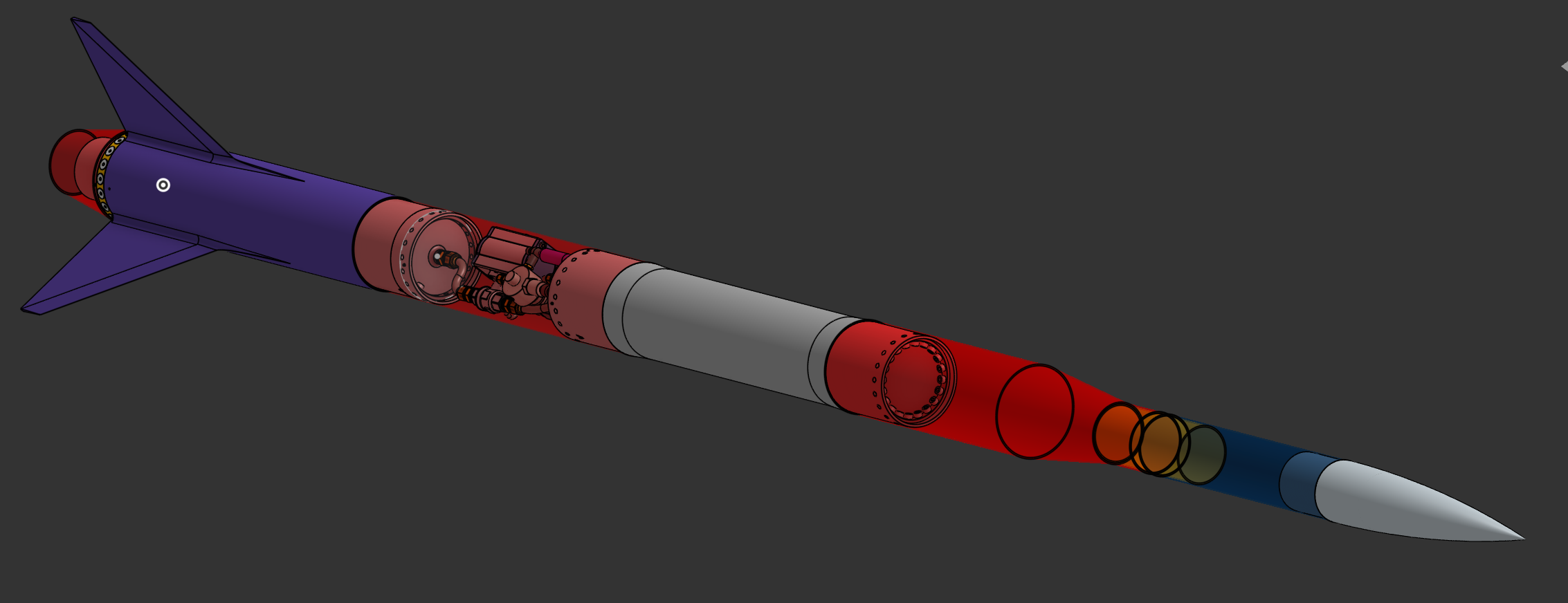

The hybrid rocket engine developed for Project Northstar is a high-thrust propulsion system utilizing liquid nitrous oxide (N₂O) as the oxidizer and potassium nitrate-coated acrylic as the solid fuel. Pottasium Nitrate serves as an initial ignition method. The chamber is constructed from 6061-T6 aluminum body with a 4.0-inch outer diameter and incorporates a 25-inch phenolic thermal liner to mitigate heat transfer to the structural casing. The fuel grain measures 23.8 inches in length and is ported to optimize oxidizer flow and regression rate. The nozzle is machined from graphite with a 1.33-inch throat diameter and custom-engineered converging/diverging angles to maximize exhaust velocity and maintain structural resilience under high-temperature conditions. The oxidizer tank stores approximately 20.96 pounds of nitrous oxide and is sealed via dual EPDM O-ring aluminum bulkheads, pressure relief valves, and instrumentation-grade pressure transducers. The system includes an onboard microcontroller-based avionics suite with a Kalman filter for real-time state estimation and thrust prediction. During initial static testing, the engine produced a peak thrust of 725 lbf with a total impulse exceeding 2,000 lbf·s.

Testing

Cold Flow Testing

Cold flow tests were performed to evaluate the injector and plumbing system under non-combustion conditions. These trials confirmed pressure vessel integrity, validated valve timing sequences, and established reliable oxidizer fill times in simulated operating scenarios.

Hot Fire Testing

A single hot fire test was conducted to validate full-system operation, focusing on ignition reliability and sustained combustion. Performance metrics including thrust profile, injector behavior, and grain regression were studied to confirm engine functionality. Data collected from this test guided refinements in injector design, thermal liner selection, and grain geometry, leading to improved ignition consistency and a more stable thrust curve.

Sensor Calibration and Validation

All pressure transducers, and load cells were calibrated prior to integration. Data collected during testing was cross-checked against simulation outputs to ensure accuracy and to confirm proper system response.

Iterative Design Process

Insights from each test cycle drove targeted design improvements in hardware construction, test layouts, procedures, injector design, and grain design.

Safety Protocols

All tests were executed remotely with redundant safety systems, including emergency cutoff valves and pressure relief mechanisms. Strict adherence to pre-test checklists and post-test inspections ensured safe and reliable operations throughout the program.

Test Discussion

During testing, the intended oxidizer tank operating pressure was not fully achieved, resulting in a lower than expected pressure differential across the injector.

This limited oxidizer flow rate, reducing the overall thrust and altering the oxidizer-to-fuel (O/F) ratio from the design target.

Despite this, the engine still achieved stable ignition and sustained combustion, allowing valuable data collection.

The test confirmed mechanical and structural integrity of the propulsion system, validating core subsystems including plumbing, injector mounting, and thermal protection.

Post-test analysis suggested the pressurization system was the limiting factor, leading to plans for increasing pressurant bottle pressure or flow capacity in future iterations.

SLU’s first ever operational hybrid rocket engine

Benjamin Khotsyphom (Structures lead), James Winkelhoch (Propulsion lead & Chief Engineer) , Hao Lai Jin (GSE Lead), Jack Herlihy (Saftey, and GSE co-lead)

Northstar V2 - Altair.

Learn about Northstar’s next iteration, and the vehicle it will fly in