Northstar Valve Wall

Engineering Project Northstar’s Valve Wall: Precision Control for Ground Testing

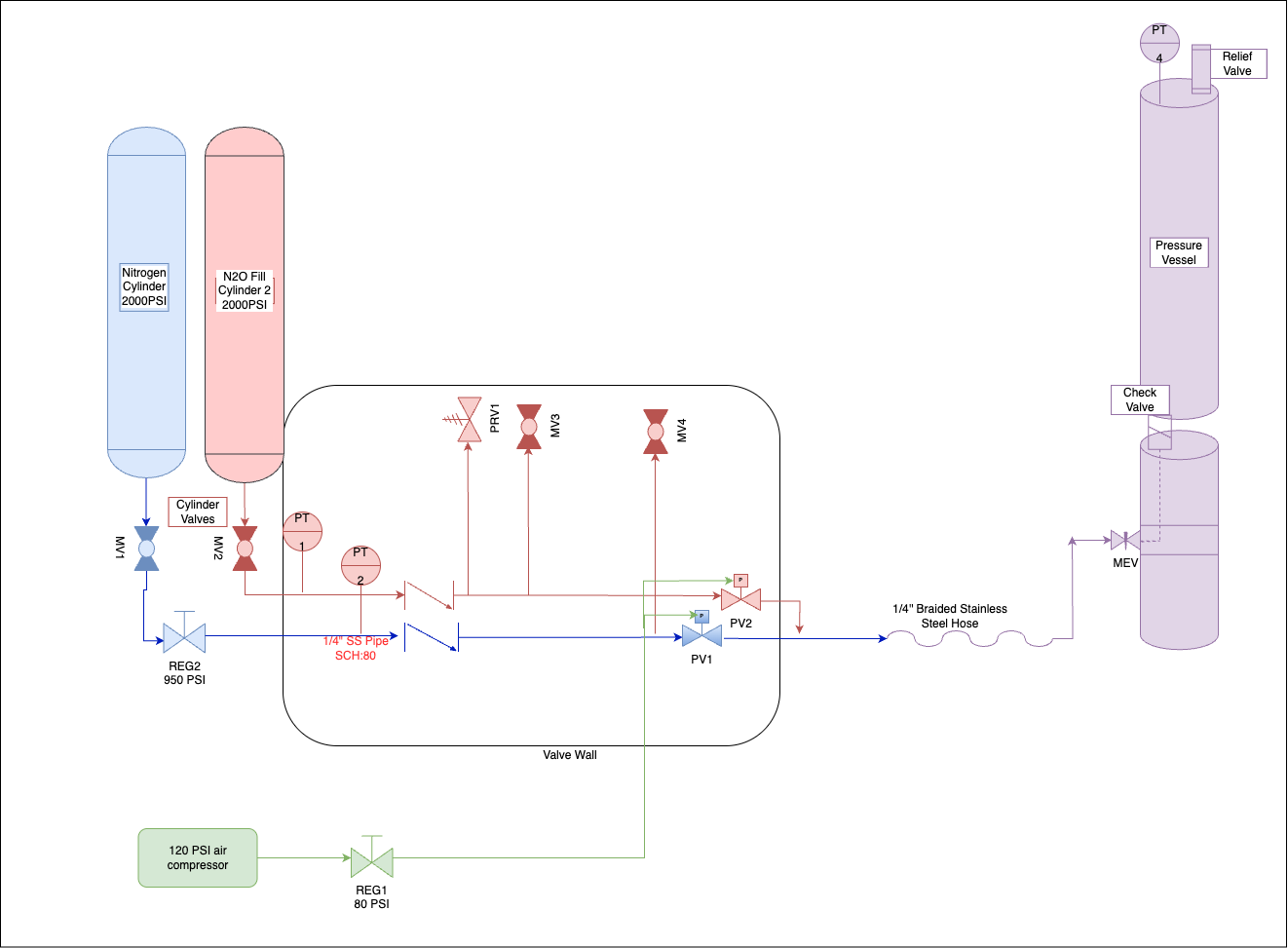

As part of the ground support infrastructure for Project Northstar, the valve wall serves as a critical subsystem enabling safe, controlled delivery of liquid nitrous oxide to the run tank during static testing.

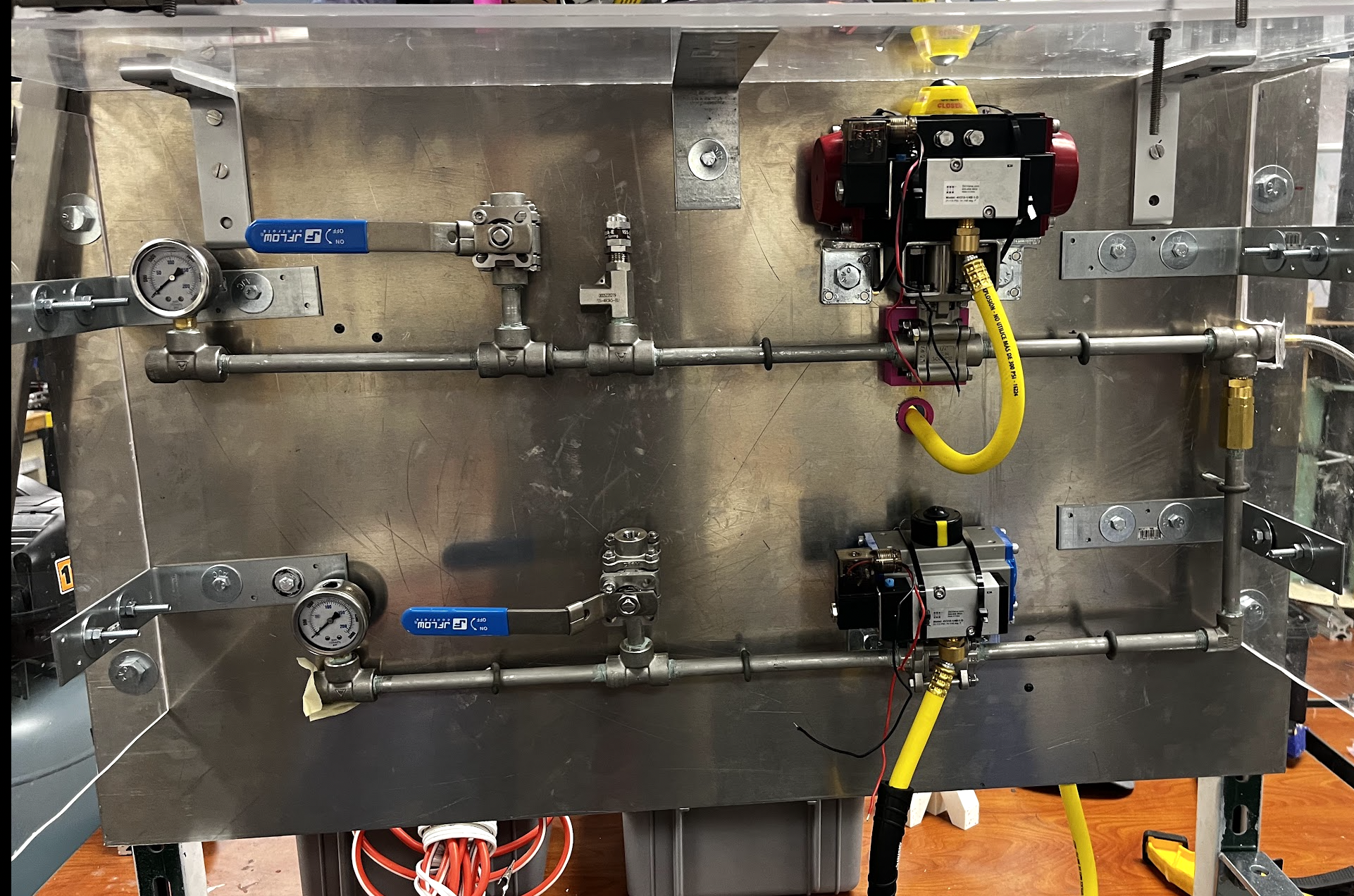

The valve wall integrates both manual and pneumatically actuated valves, along with pressure relief systems and instrumentation ports, all mounted on a robust aluminum frame. Its core functions include:

Controlled oxidizer fill and venting

Line purging for safety and system integrity

Actuation of the main fill valve via remote pneumatic control

Redundant pressure relief through dual relief valves to prevent over-pressurization

Instrumentation includes high-visibility pressure gauges and dedicated ports for pressure transducers. All fluid connections are rated for high-pressure and pre cleaned for oxygen service and then assembled with appropriate sealing techniques to prevent leaks.

The system was designed with an emphasis on operational clarity, modularity, and test-day reliability. Labeled valves reduce human error, while the overall configuration allows the propulsion team to conduct engine tests with a high degree of control and safety.

The valve wall reflects Northstar’s broader engineering philosophy: hands-on, safety-driven design executed to professional aerospace standards.

Static Test Infrastructure

Project Northstar employs a modular, field-deployable ground testing infrastructure composed of three specialized stands: the motor stand, run tank stand, and supply tank stand. Each stand is designed to support the unique mechanical, fluid, and safety requirements of hybrid propulsion testing.

Motor Test Stand

The motor stand is built from extruded T-slot aluminum, offering a lightweight, modular framework that simplifies integration and adjustment. Key features include:

1-Ton Inline Load Cell: Captures thrust during firings for accurate impulse and performance analysis.

Adjustable Mounting Hardware: Facilitates secure installation and precise alignment of the hybrid motor.

Instrumentation Compatibility: Allows for pressure sensors, thermocouples, and visual diagnostics.

Run Tank Stand

The run tank is mounted on a simple welded carbon steel frame designed for robustness and alignment. Features include:

Centering Plates: Keep the tank stable and properly oriented during pressurization.

Low-Complexity Construction: Prioritizes ease of transport and rapid field deployment.

Supply Tank Stand

The nitrous oxide supply tank is mounted to a Unistrut-based hinged stand that supports angled, inverted positioning to ensure consistent liquid draw. Key features:

Hinged Mechanism: Allows the tank to be safely pivoted into position for filling and operation.

Optimized Orientation: Ensures liquid-phase N₂O is delivered to the valve system, reducing the risk of vapor ingestion.

These three stands, used in conjunction with Northstar’s valve wall and remote control systems, provide a reliable, scalable platform for full-duration static tests and iterative motor development in a controlled environment.